Fashion and the power of transparency

“There is no beauty without truth and there is no truth without transparency” – Carry Somers

Carry Somers is the founder of Fashion Revolution , an organization that took shape in 2013 with the aim of fighting against an industry, that of fashion, which too often ignores workers' rights and the impact that the textile industry has on our planet . A movement created in response to the Rana Plaza disaster in Bangladesh, where over 1000 people died and another 2500 were seriously injured following the collapse of a clothing factory. In this sense, Fashion Revolution was the first step towards a global awareness of what it means to purchase an item of clothing: a revolution towards a more ethical and sustainable future for the fashion industry, respecting people and 'environment. A change that is more alive today than ever and which led, among other things, to the birth of the CasaGIN project. Through our natural and eco-sustainable collections, ethically made in Italy, we express our support for the Fashion Revolution and the numerous related and collateral initiatives on a daily basis. Like the #whomademyclothes communication campaign, aimed at pushing people to ask themselves where the clothes they buy come from and under what conditions they were made.

Transparency is in fact the key that allows us to understand what we are buying and what type of industry we support with our purchases . If we want more sustainable fashion, taking an interest in the origin of the products and the standards according to which they are made is an essential condition, which underlines a clear connection between, indeed, transparency and sustainability. Choosing transparency means moving towards responsibility; and where there is accountability, there is the potential for fundamental change.

This is why at CasaGIN we continue to innovate and we are proud to present you a new page on our website , dedicated to telling the story of our products in a curious and exciting way . A tour of our laboratories, the factories we collaborate with and the producers from whom we purchase the raw materials. To make our supply chain transparent, with the aim of creating an emotional connection with the chosen clothing item. But also a way to certify an ethical production, which takes into consideration the numerous operators behind the scenes who make this project possible. We want to pursue a broader purpose of ensuring good working conditions for the people who make our business possible. We have in fact chosen to spin, weave, dye and package all our garments through a network of local companies, all Italian, within which textile work is still a manufacturing art. And now we are ready to present this business network to you.

Lenzing, Austria

TENCEL™ is the registered trademark with which this Austrian company, the only company in the world to guarantee the sustainability cycle of the manufacturing process, marks the special fibers we use, obtained from eucalyptus wood (TENCEL™ Lyocell) and beech wood (TENCEL™ Modal). The production of these fibers is extremely ecological, thanks to a patented closed-circuit processing system, which starts from nature and returns to it in an absolutely eco-friendly form.

- Year of foundation: 1982

- Family management: No

- Number of employees: 6,000

- Guarantees adopted for employees: Global Code of Business Conduct

- Internal processes: Fiber production

- Products made: Underwear and clothing in TENCEL™ Lyocell and TENCEL™ Modal

- Certifications: European Ecolabel, USDA Certified Biobased Product, TUV AUSTRIA BELGIUM NV, Oeko-Tex Standard 100, FSC, PEFC, Responsible Care, Fairtrade, Standard ISO, Medically Tested, ISEGA, RCS

- Environmental policies: Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Trento, Italy

For more than 50 years this company has been one of the main players, in Italy and around the world, in the production of ecological fibres. The Group is a point of reference for quality, innovation and new models of sustainable development. A strategic choice that materializes through ECONYL®, a nylon fiber obtained by transforming waste such as fishing nets that are no longer usable and textile production waste, into a new source of opportunities.

- Year of foundation: 1969

- Family management: No

- Number of employees: 2,700

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Fiber production

- Products made: Costumes in ECONYL®

- Certifications: ISO Standard, REACH, Oeko-Tex Standard 100, EPD, GRS

- Environmental policies: Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Bergamo, Italy

This company has been producing high-performance warp-knit and circular-knit fabrics for over fifty years. Materials that represent the excellence of the Italian textile sector in the world. Experience and advanced technologies to provide a wide range of technical fabrics designed and tested to meet the numerous needs that increasingly attentive consumers require.

- Year of foundation: 1962

- Family management: Yes

- Number of employees: 350

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Weaving, dyeing

- Products made: Costumes in ECONYL®

- Certifications: REACH, ISO Standard, Oeko-Tex Standard 100

- Environmental policies: Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Varese, Italy

A company that has faced the challenges of the textile sector for several decades by continuously renewing itself and combining the traditional clothing sectors with lines more suited to the new needs that the international market requires. A guarantee of high quality and reliability that combines research into the most innovative raw materials on the market with the use of certified yarns and the most advanced dyeing and finishing techniques.

- Year of foundation: 1970

- Family management: Yes

- Number of employees: 27

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Weaving, dyeing

- Products made: GOTS organic cotton T-shirt

- Certifications: GOTS, GRS, ZDHC, Oeko-Tex Standard 100

- Environmental policies: Responsible management of chemicals

Brescia, Italy

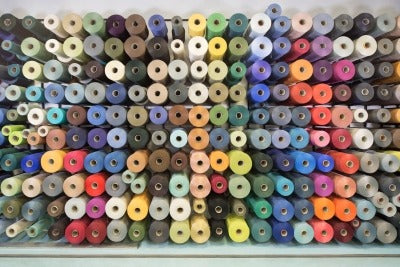

A company that has grown following the fundamental principles of quality and service, which has constantly increased the vast range of yarns offered in various types and colours, qualitatively tested along the entire production chain. A team qualified for stylistic, technical and commercial aspects is constantly engaged in researching strategic guidelines for each collection, so as to anticipate new market trends and satisfy any request.

- Year of foundation: 1993

- Family management: No

- Number of employees: 32

- Guarantees adopted for employees: National collective labor agreement, Code of ethics

- Internal processes: Spinning

- Products made: Socks in TENCEL™ Lyocell, GOTS organic cotton, recycled PET

- Certifications: GRS, RCS, GOTS, Oeko-Tex Standard 100, ZHDC, Detox

- Environmental policies: Energy efficiency, water recycling systems, improved management of natural resources, waste reduction, responsible management of chemicals

Urgnano, Italy

A leading company in the production of warp-knit elastic fabrics with the recognized ability to stimulate the creative spirit and transform its customers' ideas into concrete realities. A constantly evolving path, supported by the stimuli that the founding family has never stopped giving. Thanks to continuous innovation it stands out on the market, being appreciated for the maximum attention paid to details and for guaranteeing performance and quality of service.

- Year of foundation: 1931

- Family management: No

- Number of employees: 150

- Guarantees adopted for employees: National collective labor agreement, Code of ethics, SA8000

- Internal processes: Weaving, dyeing

- Products made: Sportswear in Amni Soul Eco®

- Certifications: Bluesign, Oeko-Tex Standard 100, ISO Standard, SA8000

- Environmental policies: Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Pordenone, Italy

Natural fabrics, precious yarns, research and sustainability are the characteristics that identify this company that has been active in the sector for a long time. An important reality in the production and marketing of tubular and open fabrics, present in the sector with a fleet of over 90 latest generation circular machines that guarantee productivity, efficiency and attention to quality.

- Year of foundation: 1979

- Family management: Yes

- Number of employees: 20

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Weaving, dyeing

- Products made: Underwear and clothing in TENCEL™ Modal

- Certifications: Oeko-Tex Standard 100

- Environmental policies: Energy efficiency

Venice, Italy

Located a stone's throw from Venice, this company has grown and modernized with full respect for the environment, while maintaining its characteristics of family management. The entire manufacturing cycle of the garments produced is completed within it: from the study of the model to its creation, from the selection of strictly Italian raw materials, to the final packaging and quality control.

- Year of foundation: 1982

- Family management: Yes

- Number of employees: 14

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Packaging

- Products made: Underwear and clothing in TENCEL™ Modal

- Certifications: 100% Made in Italy

- Environmental policies: Energy efficiency, improved management of natural resources, waste reduction, responsible management of chemical substances

Padua, Italy

The constant commitment of a team of expert professionals develops innovative fashion and design ideas on a daily basis, using only quality raw materials and keeping constantly updated with market demands. The philosophy of the hosiery has always been to guarantee the customer a line of 100% Made in Italy socks, characterized by high quality standards and a unique and unmistakable style.

- Year of foundation: 1976

- Family management: Yes

- Number of employees: 5

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Packaging

- Products made: Socks in TENCEL™ Lyocell, GOTS organic cotton, recycled PET

Rovigo, Italy

A small artisan workshop that aims to research details and find the best way to package garments, making the most of many years of experience in this sector. Today this group of experts stands out for its ability to identify the best cutting and sewing techniques so as to perfectly create each commissioned garment. Passion and dedication make this reality a point of reference in Made in Italy.

- Year of foundation: 1984

- Family management: Yes

- Number of employees: 12

- Guarantees adopted for employees: National collective labor agreement

- Internal processes: Packaging

- Products made: Costumes in ECONYL®

- Environmental policies: Improved management of natural resources, waste reduction

Choosing what we buy means choosing the world we want: each of us has the power to change things and any moment is a good time to start doing so. This is why at CasaGIN we wish to offer everyone the tools necessary to consciously choose: not only where and under what conditions our garments are made, but also how much it is possible to contribute in terms of saving resources, through ecological and eco-sustainable production processes. Transparency leads to accountability, and accountability makes change possible.