ECONYL® Regenerated Nylon - Giving Waste a New Life

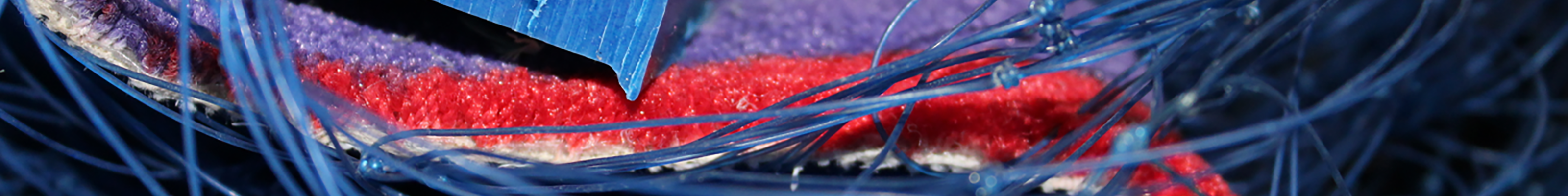

ECONYL® yarn is a 100% regenerated nylon fiber produced using nylon waste that would otherwise pollute the Earth , such as fishing nets, carpets and industrial plastics.

ECONYL® regenerated nylon has the same characteristics as that from standard sources, with no difference in quality or performance, but it can be recycled infinitely, without ever losing any of its qualities.

The winning formula of ECONYL® regenerated nylon lies in the possibility of creating new products without using new resources .

Let's reduce our impact on the planet

In addition to being an excellent solution to valorize waste, using regenerated nylon means being sensitive to the problem of climate change. ECONYL® reduces its impact on global warming potential by 90% compared to common nylon produced from petroleum.

For every 10,000 tons of raw material needed to produce ECONYL® yarn, 70,000 barrels of crude oil and 65,100 tons of CO2 eq. emissions can be saved.

Nothing is created, nothing is destroyed, but everything is transformed

The ECONYL® regeneration process begins with the recovery of waste from around the world. Once cleaned, processing begins to recover as much nylon as possible. Through an innovative purification process, the waste is regenerated to its original quality. The ECONYL® regenerated nylon is spun again to produce our clothing.

This yarn allows us to create an eco-sustainable fabric made in Italy with countless technical characteristics.

ECONYL® has various textile certifications including ISO and EPD for the verification of the materials used for production and the state of the factories. While for the chemical substances used in the production processes Aquafil, an Italian company producing the yarn, is certified Oeko-Tex Standard 100 and complies with the REACH Regulation (drafted in collaboration between Greenpeace and the European Community).

Nylon ECONYL® Infinite possibilities of use

We use ECONYL® regenerated yarn for both our swimwear collection and our sportswear. Our swimwear line is characterized by a perfect fit and breathability, it also guarantees UVA protection of +50 , resistance to sun creams and oils , excellent coverage and ultra resistance to chlorine.

In our sportswear line we value its incredible softness, the quality of being a muscle-containing tissue, slowing down the formation of lactic acid and promoting recovery of physical form and resistance to pilling. Our desire to create new products is infinite. The planet's resources are not. But that's okay, because we can have both: new products and a better environment.

We choose the best, for the body and for the environment

The ECONYL® circular regeneration process transforms waste into a new source of opportunity . Fishing nets abandoned in the seas are recovered and transformed into a new thread. A fiber that can be regenerated, recreated and remodeled infinitely, reducing its impact on global warming potential by 80%, compared to common nylon produced from oil. The ECONYL® circular regeneration process transforms waste into a new source of opportunity. Fishing nets, used carpets and industrial plastics are recovered and transformed into a new thread. ECONYL® nylon is a fiber that can be regenerated, recreated and remodeled infinitely, reducing its impact on global warming potential by 90%, compared to common nylon produced from oil.